How Packaging Affects Lactase Pill Shelf Life

Learn how packaging and storage conditions impact the shelf life and effectiveness of lactase pills for lactose intolerance.

Lactase pills help people with lactose intolerance enjoy dairy without discomfort. But did you know their effectiveness depends heavily on how they’re packaged and stored? Here’s what you need to know:

- Key Factors That Degrade Lactase Pills: Heat, humidity, and light can break down the enzymes, reducing their ability to digest lactose.

- Best Packaging Materials: Aluminum offers the best protection against moisture, oxygen, and light. Glass works well but is heavy and fragile. Plastic is lightweight and affordable but varies in effectiveness.

- Proper Storage Tips: Keep pills in a cool, dry, and dark place (below 77°F). Avoid bathrooms or areas with high humidity. Always reseal the container tightly to limit air exposure.

- Common Mistakes: Storing pills in direct sunlight, near heat sources, or frequently opening the container can reduce potency.

For maximum shelf life, choose products with high-quality packaging and store them properly. These simple steps ensure your lactase pills work when you need them most.

What Affects Lactase Pill Shelf Life

The effectiveness of lactase pills can change over time due to various environmental and material factors. These elements either help preserve or degrade the enzymes, which explains why some pills lose their potency faster than others, even when they share the same expiration date. Let’s dive into how temperature, humidity, and light influence the stability of these enzymes.

How Temperature, Humidity, and Light Affect Pills

Temperature plays a major role in the stability of lactase enzymes. Studies reveal that heat significantly reduces lactase activity. For example, lactase stored at 80°C for just one week retained only 64% of its activity. While enzymes may recover some functionality after heat exposure, this recovery is usually incomplete, making proper storage essential.

Humidity is another critical factor. Moisture can trigger chemical reactions that degrade the enzyme, so controlling humidity levels during storage is key to maintaining lactase activity.

Light exposure also poses a threat. Ultraviolet and visible light can break the enzyme’s chemical bonds, leading to a gradual decline in activity. To combat this, many manufacturers use dark-colored bottles or opaque packaging to shield the pills from light.

How Packaging Materials Protect Pills

Packaging acts as the first line of defense against environmental factors that can degrade lactase enzymes. Different materials provide varying levels of protection, which directly impacts the product's quality and freshness during storage and distribution.

| Material | Key Advantages | Main Limitations |

|---|---|---|

| Glass | Blocks gases and vapors, chemically stable, protects light-sensitive contents with tinted glass | Heavy, fragile, high shipping costs |

| Aluminum | Excellent barrier against moisture, oxygen, and light; recyclable and formable | Higher production cost, not weldable |

| Plastic | Lightweight, affordable, flexible, resistant to chemicals, heat-sealable | Permeability to light, gases, and vapors varies |

Aluminum packaging is particularly effective for protecting enzymes. Its ability to block moisture, oxygen, and light makes it a top choice for sensitive formulations. According to Cixi Aolijue Metal Products Co.,Ltd:

Aluminum packaging effectively resists external environmental influences, ensuring product integrity and shelf life. It preserves freshness, stability, and efficacy, making it ideal for sensitive formulations. Aluminum bottles appear more premium, enhancing product appeal and improving brand perception.

Plastic, while budget-friendly and convenient, has limitations. Its protective qualities can vary, meaning not all plastic packaging offers sufficient protection for lactase enzymes.

Glass containers are highly effective at blocking gases and vapors, with excellent stability. However, their weight and fragility make them less practical for portable use.

The choice of packaging can significantly impact the stability of lactase enzymes, as we’ll explore further.

Why Enzymes Break Down Over Time

Lactase enzymes work by breaking down lactose into glucose and galactose. Their ability to function depends on maintaining their three-dimensional structure. When this structure is damaged, the enzyme loses its effectiveness.

Several factors contribute to lactase degradation:

- Molecular instability: Heat, light, moisture, and oxygen can disrupt the enzyme’s chemical bonds, reducing its activity.

- Oxidation: Over time, oxygen exposure modifies amino acids in the enzyme, hindering its ability to process lactose.

- pH changes: Lactase enzymes are sensitive to shifts in acidity or alkalinity, which can further destabilize their structure.

Proper packaging helps protect against these threats, preserving the enzyme’s integrity. For best results, lactase pills should be stored at room temperature, below 77°F (25°C), and away from heat. Pills should also be discarded after their expiration date, as enzyme activity continues to decline over time.

Research on Different Packaging Materials

Several studies have explored how different packaging materials protect enzyme-based products from environmental factors that accelerate degradation. These investigations reveal clear differences in how materials perform when used for packaging lactase pills and other sensitive supplements.

Glass, Plastic, and Aluminum Packaging: A Comparison

The choice of packaging material plays a crucial role in maintaining enzyme stability. For instance, a study by Allinson et al. found that tablets stored in PVC plastic blisters experienced a 26% degradation after six months under stress conditions (104°F and 75% relative humidity). This was attributed to PVC's relatively high moisture permeation rate of 0.259 mg per blister per day. In contrast, cold-form aluminum blisters performed significantly better, with a permeation rate of just 0.001 mg per blister per day, resulting in almost no degradation.

Amber glass offers another effective option, as it blocks UV light and gases, helping to preserve enzyme integrity. However, its heavier weight and fragility can make it less practical than other materials.

Among all options, aluminum packaging stands out for its ability to resist environmental factors, ensuring product stability and freshness. Plastic materials, while lightweight and cost-effective, show varying levels of permeability to light, gases, and moisture. Innovations like PCTFE (Polychlorotrifluoroethylene) films have improved plastic's moisture barrier capabilities, offering up to 30 times better protection than standard PVC. However, these advanced materials can raise production costs.

Extending Shelf Life Through Advanced Packaging

Beyond material selection, specific packaging features can significantly enhance the shelf life of enzyme-based products. By minimizing exposure to moisture and oxygen, advanced packaging methods help prevent hydrolysis and degradation. For example, alu-alu (aluminum-aluminum) strip packaging is far more effective at blocking water vapor and oxygen compared to PVC-aluminum blister packaging, resulting in longer shelf life and better retention of enzyme potency.

Emerging technologies in active packaging also show promise. In laboratory tests, packaging films infused with immobilized lactase enzymes retained 13.41% of enzyme activity in dry storage and 62.52% in wet storage conditions. This innovative approach could further enhance the effectiveness of enzyme supplements over time.

Research consistently shows that aluminum-based packaging provides the best protection for lactase pills, followed by amber glass. Standard plastic materials, while more affordable, offer the least effective barrier. These findings emphasize the importance of selecting packaging that aligns with proper storage conditions to preserve enzyme potency.

How Storage Conditions Affect Pill Effectiveness

Proper storage is crucial for maintaining the potency of lactase pills. While sturdy packaging offers some protection, factors like temperature, humidity, and light can degrade the enzymes over time. Knowing how to store your pills correctly ensures they remain effective until the expiration date.

Best Storage Practices for Maximum Shelf Life

To keep lactase pills effective, store them at temperatures between 59°F and 86°F (15°C–30°C). Many manufacturers recommend staying below 77°F (25°C) for better stability. This range helps protect the enzymes from breaking down.

Avoid refrigerating lactase pills. While refrigeration might seem like a good idea, it can introduce moisture when the container is opened. Temperature changes can lead to condensation, which speeds up enzyme degradation. Instead, store them in a dry, cool area.

Light exposure is another factor to watch out for. Enzymes degrade when exposed to light, so keep the pills in a dark, enclosed space like a medicine cabinet or pantry. Bright light or direct sunlight can be especially harmful, particularly if the pills are in clear or translucent packaging.

A study by Popescu et al. (2021) revealed that lactase enzymes remain stable at temperatures up to 113°F (45°C), but their activity drops significantly at higher temperatures.

Common Storage Mistakes That Reduce Potency

Certain storage habits can quickly reduce the effectiveness of lactase pills. Understanding these mistakes can help you avoid them.

| Storage Mistake | Consequence | Prevention |

|---|---|---|

| Exposure to Air | Enzyme degradation | Keep the container tightly sealed |

| Moisture | Enzyme breakdown | Store in a dry area; avoid damp places |

| Heat | Enzyme degradation | Keep away from heat sources |

| Light Exposure | Enzyme weakening | Store in a dark, enclosed space |

| Frequent Handling | Reduced enzyme stability | Minimize opening the container |

| Storing in a Bathroom | Faster degradation | Choose a cool, dry location instead |

| Leaving the Container Open | Reduced effectiveness | Always reseal the container tightly |

| Exposure to Direct Sunlight | Weakens enzymes | Store in a shaded area |

| Placing Near Heat Sources | Accelerates breakdown | Keep away from stoves or radiators |

Temperature fluctuations during storage can also harm the pills. Changes during transportation or storage increase the risk of losing enzyme quality.

Extreme heat is particularly damaging. Research shows that lactase enzymes begin to lose activity above 104°F (40°C) and become completely inactive at temperatures exceeding 131°F (55°C).

Additionally, frequent container opening exposes the pills to air, moisture, and light. To minimize this, only take out the amount you need and reseal the container immediately.

Industry Standards for Lactase Pill Packaging

The FDA has established strict guidelines for enzyme supplement packaging to ensure consumer safety and maintain product quality. These rules cover everything from the materials used to the information displayed on labels, guaranteeing that lactase pills retain their potency. These regulations work hand-in-hand with the packaging and storage practices previously discussed, ensuring the enzymes remain effective from production to consumption.

FDA Requirements for Enzyme Supplement Packaging

The FDA oversees enzyme supplements under dietary supplement regulations, requiring adherence to current good manufacturing practices (CGMPs). These practices address key factors such as identity, purity, quality, strength, and composition. Packaging plays a critical role in preserving enzyme activity. The primary container must protect the product from degradation, contamination, and exposure to light or air. Specifically, it needs to prevent moisture and oxygen from reaching the enzymes, as these elements can significantly reduce their effectiveness.

Secondary packaging provides an added layer of protection, shielding the product from excess moisture and physical damage during shipping and storage. This often includes outer boxes or protective wrapping. Additionally, the Poison Prevention Packaging Act of 1970 requires child-resistant features, such as safety caps or blister packs, for many pharmaceutical products. Over-the-counter enzyme supplements must also use tamper-resistant packaging to clearly indicate any signs of tampering.

Labeling is another crucial aspect. FDA regulations require dietary supplement labels to include a Supplement Facts panel, a complete ingredient list, and the manufacturer’s name and location. Labels must remain securely attached and legible throughout the product's shelf life. For enzyme supplements, this includes clear information on dosage, usage warnings, and storage instructions.

Maintaining proper temperature and humidity is vital during manufacturing and repackaging. Facilities are required to control environmental factors such as temperature, humidity, light, air quality, and dust. When products are repackaged, they must include labels with batch numbers, repackaging dates, storage guidelines, and beyond-use dates.

milktab's Packaging and Quality Testing

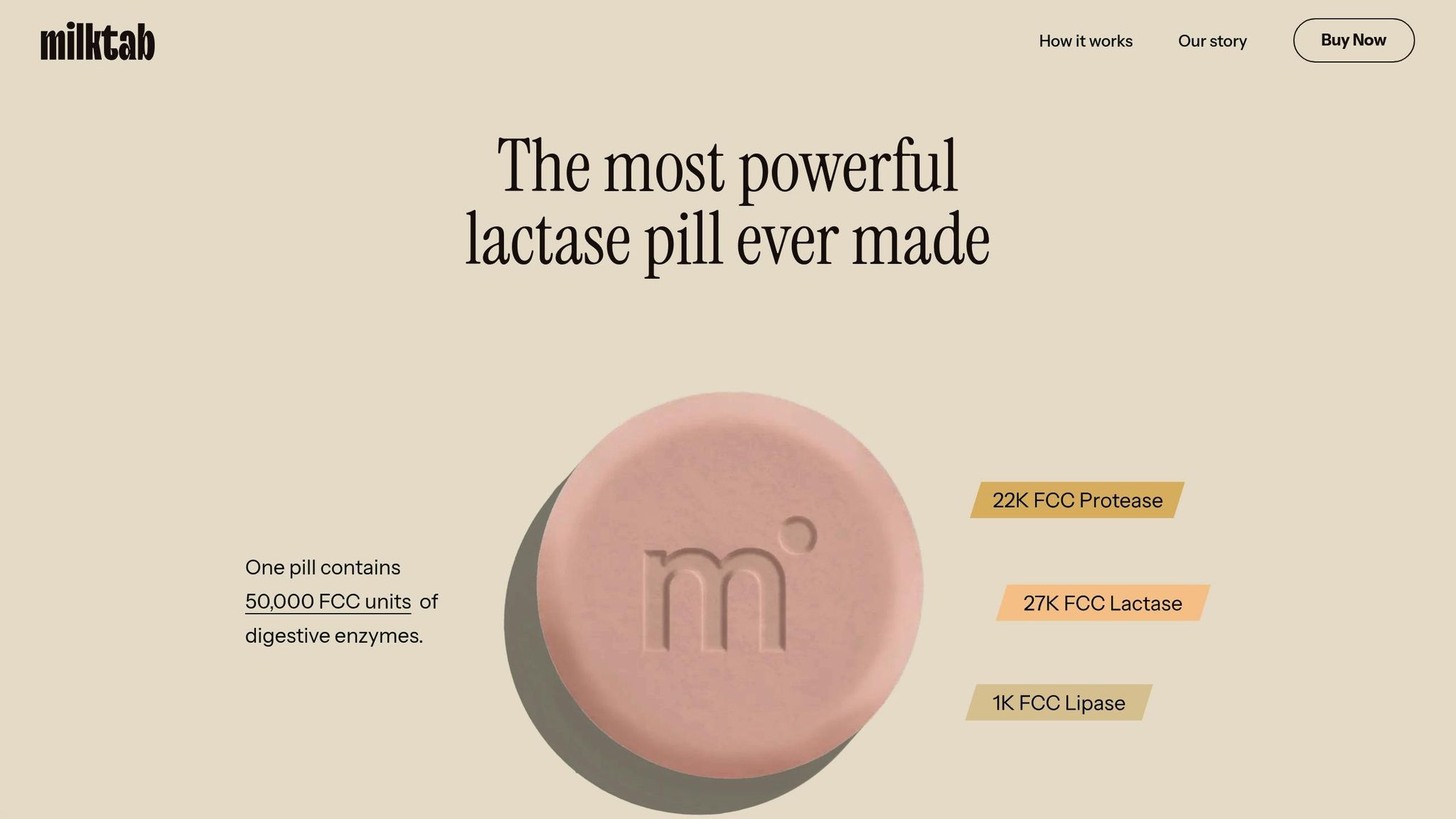

milktab takes these FDA standards seriously and goes a step further, demonstrating how a company can ensure both compliance and product effectiveness. Their packaging is compact yet highly protective, designed to safeguard their triple-enzyme formula. This formulation includes 27,000 FCC units of lactase, 22,000 FCC units of protease, and 1,000 FCC units of lipase. Given the potency of this blend, the packaging is carefully designed to preserve enzyme activity over the product’s shelf life.

To reinforce quality assurance, milktab employs third-party testing beyond standard FDA requirements. This independent verification ensures the packaging effectively maintains enzyme potency and that the product consistently meets its label claims.

Customer feedback underscores the importance of proper packaging in preserving the product's effectiveness. In May 2025, a verified Amazon customer shared that a single milktab tablet provided excellent enzyme support, highlighting the role of packaging in maintaining potency. Another customer noted they could enjoy dairy without discomfort after using milktab. One reviewer emphasized the product's convenience and reliability:

"Works so well! No upset stomach when eating ice cream. The little pack slips right into my purse - definitely worth it." – James

milktab holds a 4.2 out of 5-star rating on Amazon, based on 61 reviews. Many customers praise the product’s compact size and consistent performance. These reviews suggest that milktab’s packaging strikes the right balance between convenience and protection, meeting both regulatory standards and customer expectations.

Conclusion

Studies highlight that proper packaging plays a key role in maintaining enzyme potency, making careful handling just as important.

Factors like heat, humidity, and sunlight can significantly impact the stability of lactase enzymes. High temperatures speed up enzyme breakdown, humidity can damage capsules and reduce their effectiveness, and direct sunlight accelerates degradation. This makes both high-quality packaging and mindful storage habits essential for preserving enzyme integrity.

Here are some practical storage tips for consumers: Keep pills in a cool, dry, and dark location, away from heat sources. A dedicated pill organizer stored in a controlled environment can help maintain their quality and make tracking usage easier. Avoid storing supplements in bathrooms, where moisture levels are high, and always ensure containers are tightly sealed to limit air exposure.

While FDA regulations set the standard for packaging, your everyday storage choices have a direct impact on the effectiveness of your supplements. Look for products with protective packaging and third-party testing to ensure quality.

Additionally, regularly check expiration dates and inspect pills for any changes in texture, color, or smell - these could indicate a loss of potency. By understanding these factors and following smart storage practices, you can get the most out of your lactase supplements and maintain reliable digestive support.

FAQs

How does packaging affect the shelf life and effectiveness of lactase pills?

Packaging is essential for maintaining the shelf life and effectiveness of lactase pills. Moisture, oxygen, and light can weaken the enzyme, reducing its ability to function over time. Using materials like foil or specially designed plastics creates a protective barrier, shielding the pills from these damaging elements and helping the enzyme stay stable.

Airtight and water-resistant packaging adds another layer of protection by preventing water absorption and microbial contamination. This ensures the enzyme remains active, allowing the pills to reliably support dairy digestion right up until their expiration date.

How should I store lactase pills to keep them effective until their expiration date?

To keep your lactase pills effective up until their expiration date, store them in a cool, dry spot away from heat, moisture, and air. A sealed container tucked in a bedroom drawer or another stable location works well. Steer clear of storing them in the bathroom or refrigerator unless the packaging specifically suggests it, as humidity and fluctuating temperatures can weaken the enzymes.

Using airtight containers that minimize exposure to air and moisture is another smart move to maintain the pills' potency. By storing them correctly, you ensure the enzymes stay active, helping you enjoy dairy without discomfort for as long as possible.

Why is aluminum packaging the best choice for preserving lactase pills?

Aluminum packaging is an excellent choice for protecting lactase pills. It creates a strong shield against moisture, air, light, and contaminants - key factors in keeping the pills potent and extending their shelf life.

Compared to glass or plastic, aluminum provides better defense against environmental elements that can break down the enzymes. This means your lactase pills stay effective for a longer period, ensuring their quality and reliability.